Why Switching to an Electric Heat Pump Is More Complicated Than It Seems

Electric heat pumps are widely recognized for their energy efficiency – both air-source heat pumps (ASHPs) and Heat Pump Water Heaters (HPWHs) can achieve Coefficients of Performance (COP) above 3, compared to gas furnaces and water heaters which always have COP values below 1. Depending on the relative cost of electricity vs gas per BTU of heat energy and the relative cleanness of the electrical grid that serves a home, the higher efficiency of heat pumps can lead to lower energy bills and a smaller environmental footprint when compared to gas-fired systems. While heat pumps come with a higher upfront cost, they often pay for themselves over time in both monetary savings and reduced carbon emissions.

However, the decision isn’t as straightforward as it might seem. While heat pumps are greener throughout their operation, the production of heat pumps can result in significant embodied carbon emissions.

Embodied vs. Operational Carbon

Embodied carbon refers to the greenhouse gas (GHG) emissions associated with the production and manufacturing stages of a product’s life cycle, including the sourcing, transportation, and manufacturing of the materials. Tracking embodied carbon can be very difficult because the production stages of something like a heat pump usually take place at several different facilities, sometimes all over the world; think control boards made of rare earth minerals from Asia, steel from North America, and copper mined and extruded in South America – that’s a lot to keep track of!

In contrast, operational carbon refers to the GHG emissions produced by a product throughout its use. While this term is often applied to buildings, it also relates to specific appliances like water heaters.

The reason these two types of carbon emissions are important is because while gas water heaters often have higher operational emissions, they have lower embodied emissions, due to less energy intensive components. Meanwhile, electric heat pumps often have lower operational emissions but higher embodied emissions.

A Real-Life Dilemma

Recently, BER’s President, Chris McTaggart, shared that he is considering switching out his 19-year-old gas water tank for an electric heat pump. While his current water heater functions just fine, Chris is aware of the environmental benefits of heat pumps. However, he also knows that heat pumps produce quite a bit of embodied carbon, making him wonder – would it be better to wait for the gas heater to fail before making the switch?

To make an informed decision, Chris challenged our team to calculate the embodied carbon of a heat pump and determine how long it would take to offset these emissions.

Fuel Mix: The Geographic Factor

When considering an electric heat pump, it’s important to know the fuel mix of the local electric grid. The EPA has a useful online tool called the Power Profiler that compares fuel mixes of electric grids across the U.S. We used this tool to compare the fuel mix in Michigan (where Chris’s water heater resides) to Vermont. Michigan relies primarily on coal and gas for electricity, resulting in higher overall emissions. Vermont, by contrast, has a coal-free grid, making it a cleaner energy source for operating electric heat pumps.

Fuel mix highlights how geographic factors influence operational carbon, but what about the emissions from manufacturing the appliances? This is where the concept of embodied carbon is pivotal, especially when comparing electric heat pumps and gas water heaters.

Calculating the Emissions

Estimating embodied carbon can be tricky, but RESNET recently released a draft standard for reporting and calculating embodied carbon that provides some guidance on this. However, outside of RESNET, there is limited research on this specific topic in the United States. In contrast, several studies conducted in Europe suggest higher embodied carbon outputs from both electric heat pumps and gas water heaters (see Study 1, Study 2, Study 3). This limited body of research underscores the challenges of accurately calculating embodied carbon emissions, particularly given regional differences in technology and energy sources, which makes it difficult to apply findings universally.

For the purposes of our research, we based our calculations on the RESNET standards. According to their findings, the embodied carbon of an electric heat pump is approximately 600 kg, compared to 200 kg for a gas water heater.

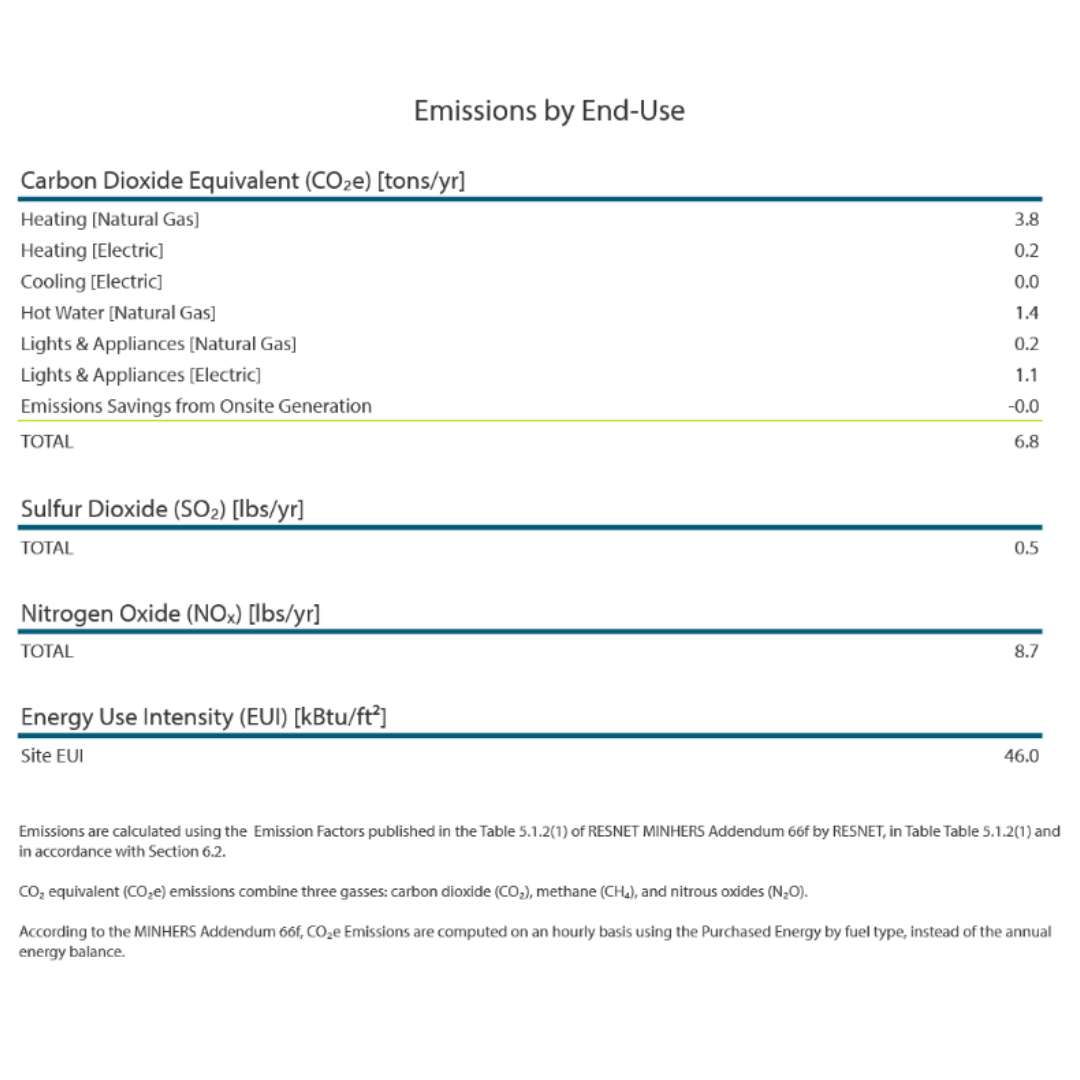

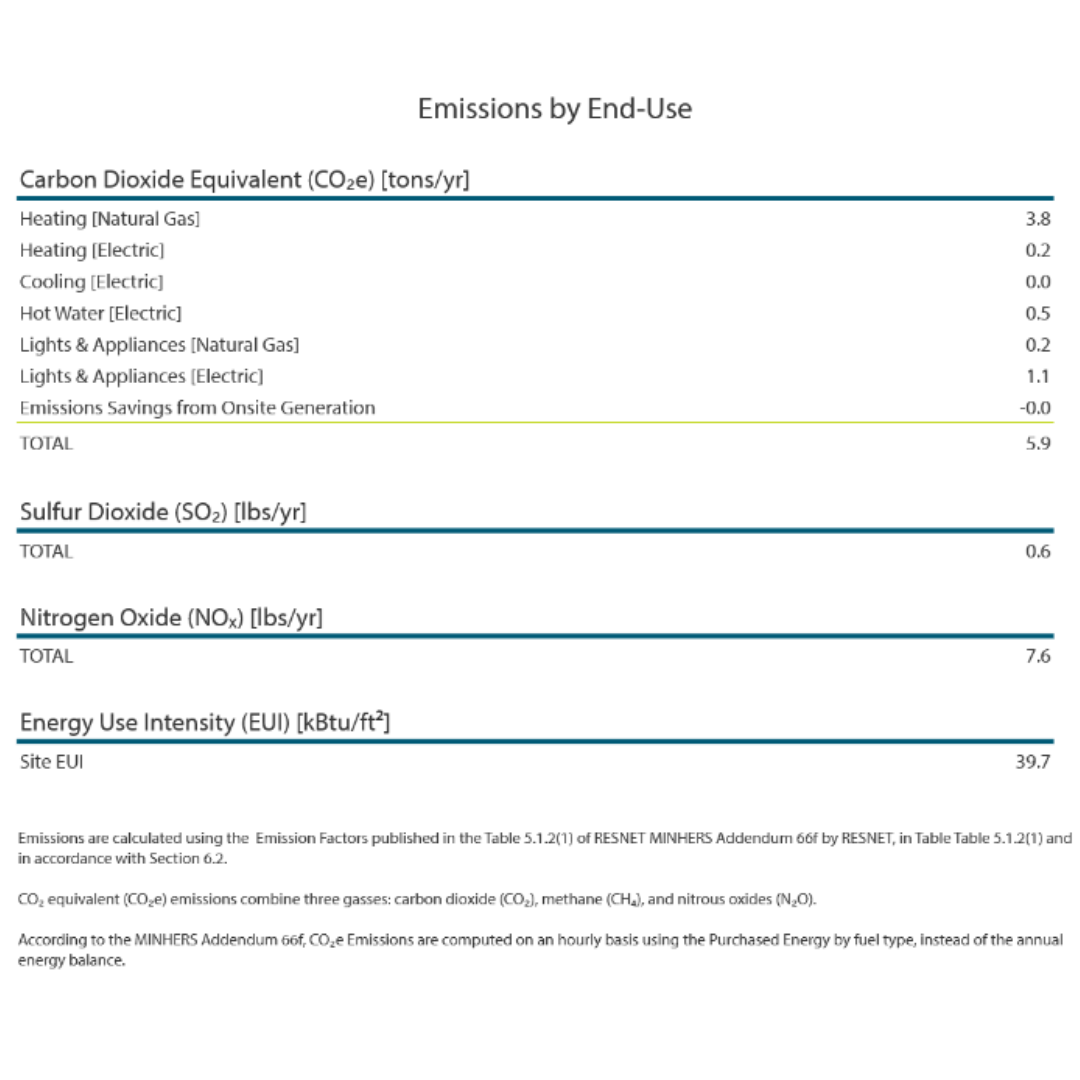

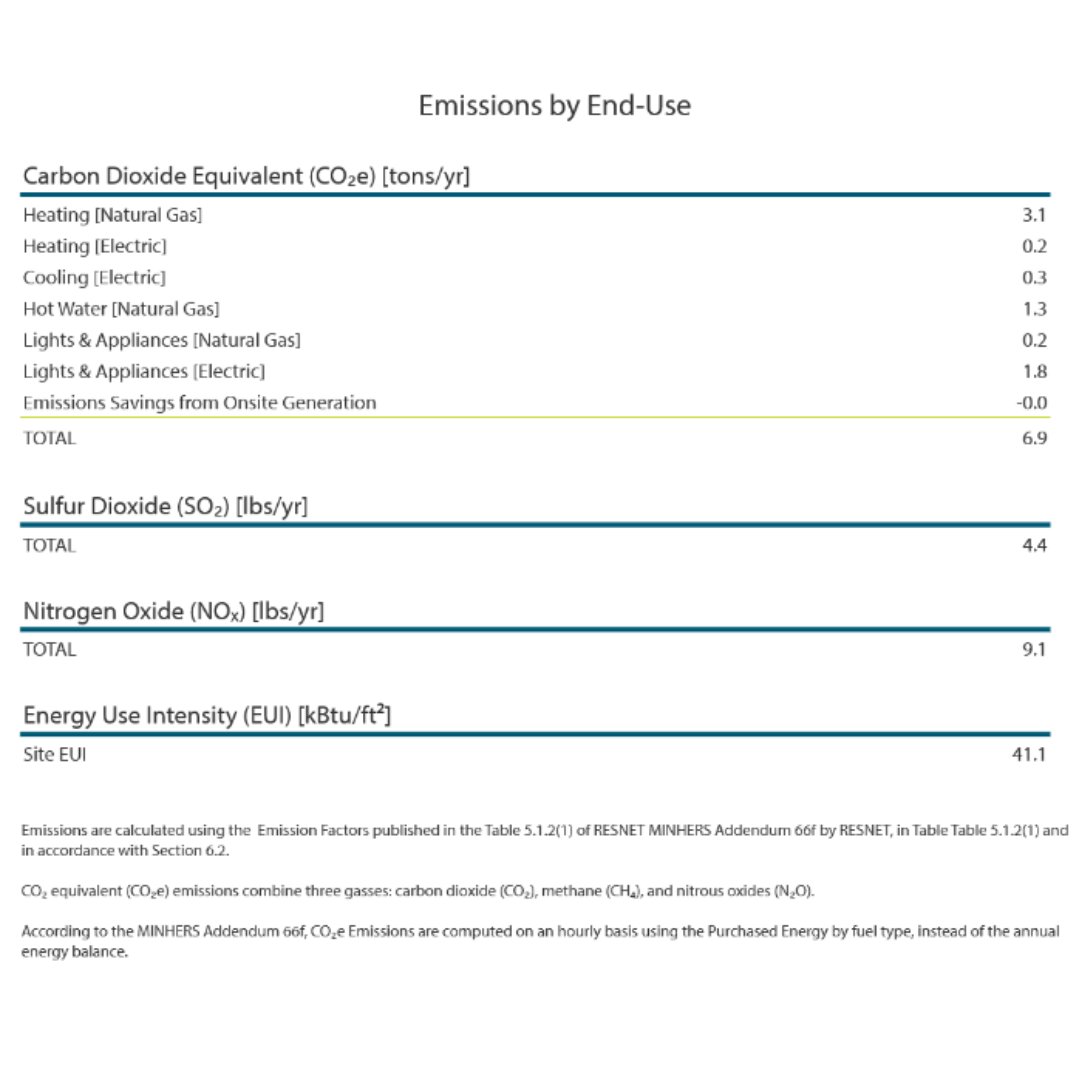

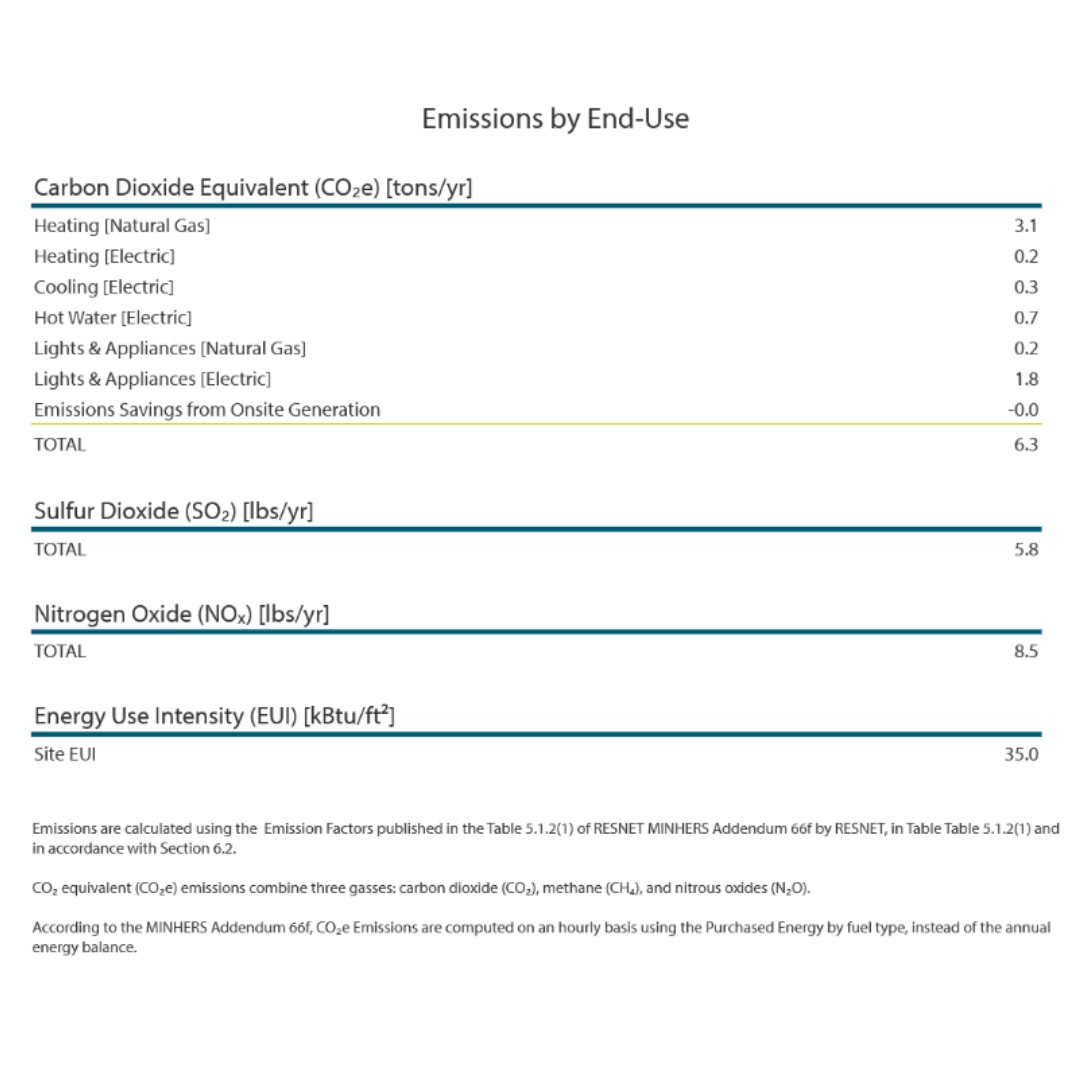

Using Ekotrope, we analyzed the overall emissions by end-use of an electric heat pump and a gas water heater in both Michigan and Vermont . In Michigan, the CO2 emissions savings from having a heat pump are around 0.6 tons (544 kg) per year. When we take the 600 kg of embodied carbon and divide it by the savings, we can see that it will take a little over a year for the heat pump to pay for itself in terms of offsetting the embodied carbon.

In Vermont, the savings are even better because of the cleaner grid, with a heat pump saving 0.9 tons (816 kg) per year of CO2 emissions. In this case, it will only take about 8 or 9 months for the heat pump to offset the embodied carbon.

Click the images below to reveal the findings

Given that heat pumps typically last about 15 years, it makes more sense practically and environmentally for Chris to make the switch to an electric heat pump sooner rather than later. Even though his gas water heater is working fine, it will continue to produce more CO2e than an electric heat pump would.

The Bottom Line

The decision to switch to an electric heat pump involves more than just operational efficiency—it requires understanding the full lifecycle impact of the appliance. While the numbers aren’t perfect, they highlight the importance of evaluating embodied carbon alongside operational emissions.

For consumers, a good starting point is researching the fuel mix of your region. A cleaner grid makes the switch to an electric heat pump even more beneficial. Tools like the EPA’s Power Profiler can provide valuable insights.

That said, the challenge of tracing embodied carbon highlights a broader issue: the lack of transparency in supply chains. Manufacturers must be held accountable for recording and sharing emissions data across all stages of production.

Until technology and accountability improve, consumers need to take an active role in learning about the products they buy and their true environmental impact. By making informed choices, we can collectively reduce CO2 emissions and promote a more sustainable future.

If you want to learn more about embodied and operational carbon in the green building industry, check out this other article from BER!

______

Other Resources