Operational vs Embodied Carbon

What is the difference between operational carbon and embodied carbon? What it is and why you should care:

Carbon vs… Carbon?

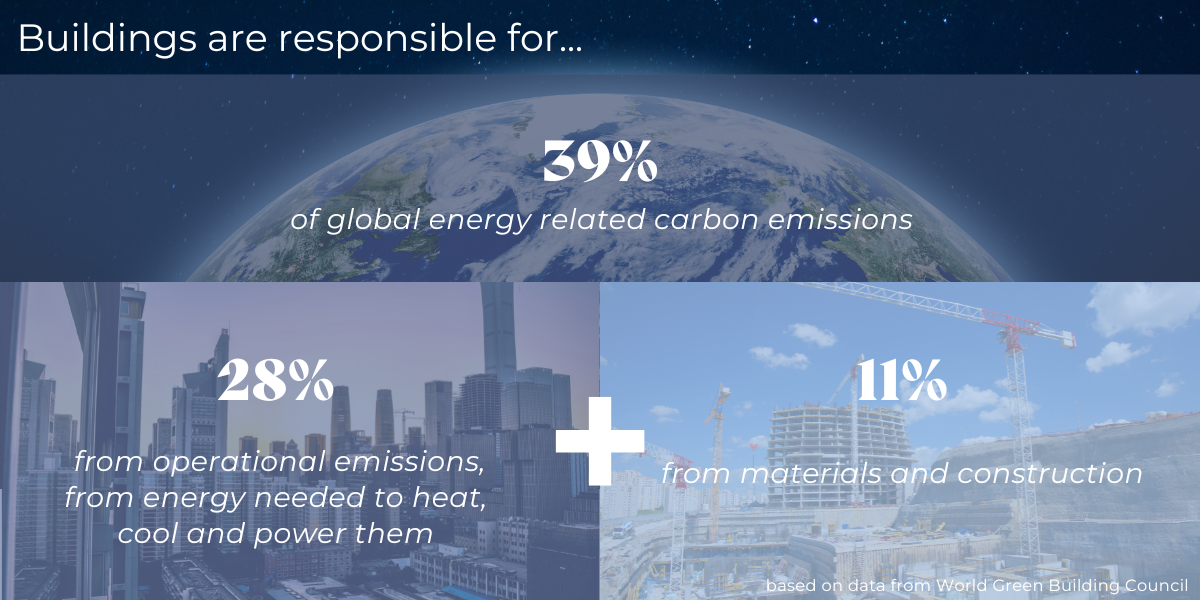

In the field of green building and the sustainable built environment, the term “carbon” is commonly used as shorthand terminology for greenhouse gas (GHG) emissions, measured in units of CO2e or equivalent CO2 emissions. “Carbon”, in this context, also includes the emissions of non-carbon greenhouse gases such as methane and “reports on emission reductions commonly use the word carbon when they really mean greenhouse gas,” (RESNET).

As you read through this blog article and future articles of this series, and engage with other professionals on the topic of carbon, it is important to remember that the term “carbon” will frequently also refer to pollution factors that aren’t specifically CO2 emissions, but also many other chemical emissions which exacerbate climate change potential, such as refrigerants used in heating/cooling systems and blowing agent chemicals used the production of certain building products like XPS insulation.

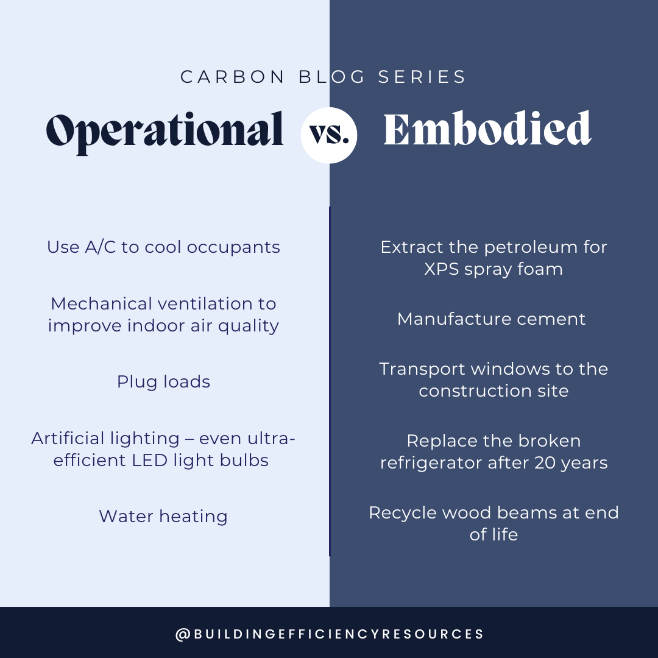

So that’s carbon, but what is operational carbon?

As a HERS Rater, you are working to address operational carbon – GHG emissions produced through the energy use of a building. In fact, the industry has done such a great job addressing it that we have reduced operational carbon emissions from energy use in residential buildings by over 19% in the last 15 years (C2ES).

RESNET’s new Carbon Index was developed to provide a more accurate metric of measuring operational carbon emissions, which can be easily aligned with organizational decarbonization goals. Rather than comparing apples (CO2e) to oranges (energy savings in dollars or kilowatt-hours), the new index enables organizations to easily compare apples to apples and accurately assess impact or progress towards a set decarbonization goal, measured in CO2e. The new RESNET Carbon Rating Index has already been programed into the latest version of REM software, and likely will be in Ekotrope soon, so that CO2e and the Carbon Index can be calculated at the same time that the HERS index is calculated, with no additional input data.

Taking it one step farther, the new RESNET CO2 Rating Index Standard for operational carbon will blend seamlessly into future developments and offer a more wholistic look at the total GHG emissions of a building, factoring both operational and embodied carbon into design choices.

Looking ahead: Embodied Carbon

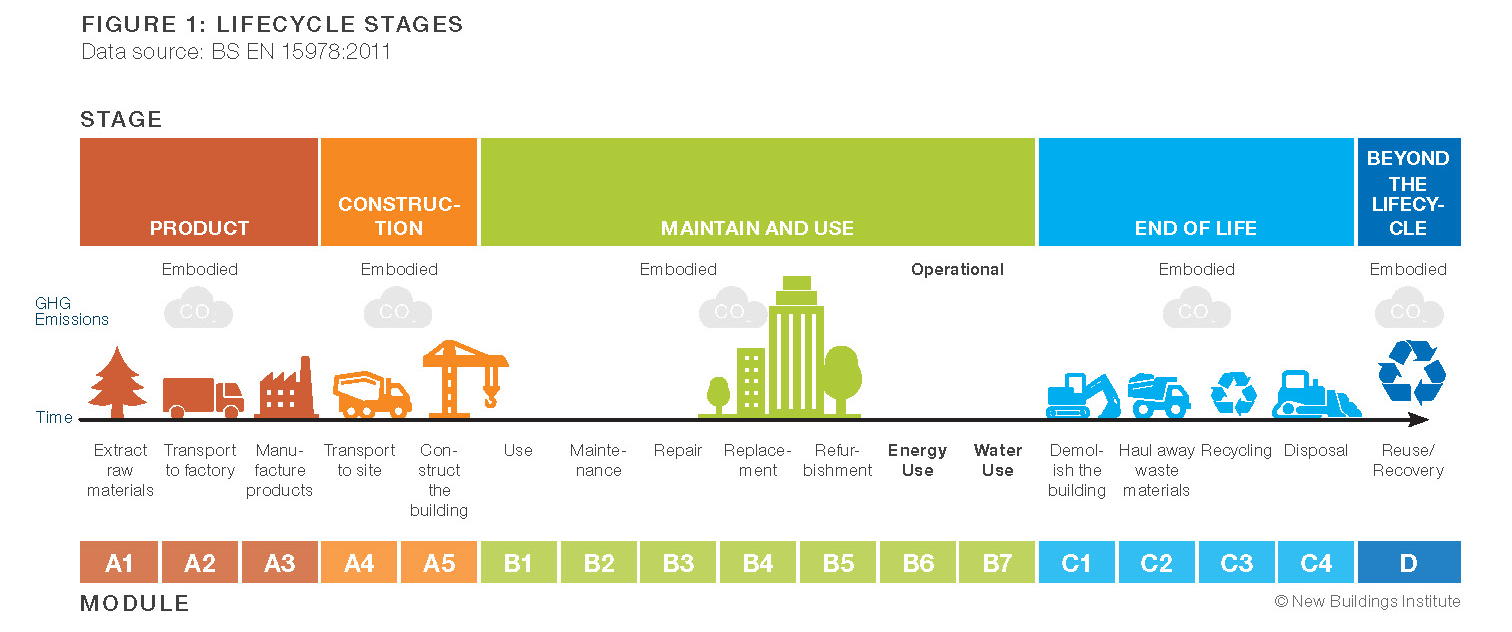

Operational and embodied carbon during a building’s life cycle. Image from New Buildings Institute.

Embodied carbon, also commonly referred to as embodied CO2e and/or Global Warming Potential (GWP), is the GHG emissions associated with materials and construction processes throughout the whole life cycle of a building or infrastructure. “Unlike with operational carbon, there is no chance to decrease embodied carbon with updates in efficiency after the building is constructed,” making it pertinent to address embodied carbon as we continue to construct new buildings to accommodate an ever-growing global population (Carbon Leadership Forum).

How can HERS Raters help address Embodied Carbon?

Approximately 70% of the embodied carbon of a building comes from the manufacturing of materials (Stages A1-A3). But, builders aren’t the ones manufacturing the materials — they’re just looking for the most bang for their buck in an insulation with a high R-value, right? For the design team, it boils down to identifying manufacturers that produce low embodied carbon materials and comparing a variety of options using Life Cycle Assessment (LCA) tools.

Just like HERS Raters are the expert resource for builders on all things energy and operational carbon, HERS Raters hold the potential to be the go-to resource for embodied carbon as well. HERS Raters already create projected energy models to help inform design decisions, and Raters already collect important data on the envelope assemblies, appliances, etc., to provide a concrete value (HERS Index score) to the outcome of those decisions. Embodied carbon fits smoothly into the scope of work for HERS professionals and further fosters the teamwork-oriented relationship between HERS Raters and builders.

RESNET is forming committees and working groups to develop an embodied carbon index (or similar scoring system) and ICC is working on integrating embodied carbon into ICC 2024 codes, so BER is here to help you navigate these exciting upcoming changes in the building performance industry.

Definitions for next time:

- Global warming potential (GWP) is the most common metric for measuring, evaluating, and reporting materials’ greenhouse gas emissions over a product or building’s lifecycle, also called embodied carbon or embodied CO2e.

- An Environmental Product Declaration (EPD) is an independently verified and registered document that communicates transparent and comparable information about the life-cycle environmental impact of products. The responsibility of providing an EPD lies in the hands of manufacturers worldwide.

- Lifecycle assessment (LCA) is an independently verified study of a product or building. Product-level LCAs must be done in accordance with ISO 14040 and ISO 14044 for incorporation in a product’s environmental product declaration.

- Whole building LCA (WB LCA) evaluates all the products and materials used in a building, or scope, to determine the carbon emissions associated with the materials.

Got questions?

Let us know! This blog series is intended to address any questions you may have about carbon emissions and we want your input in helping to craft the series.